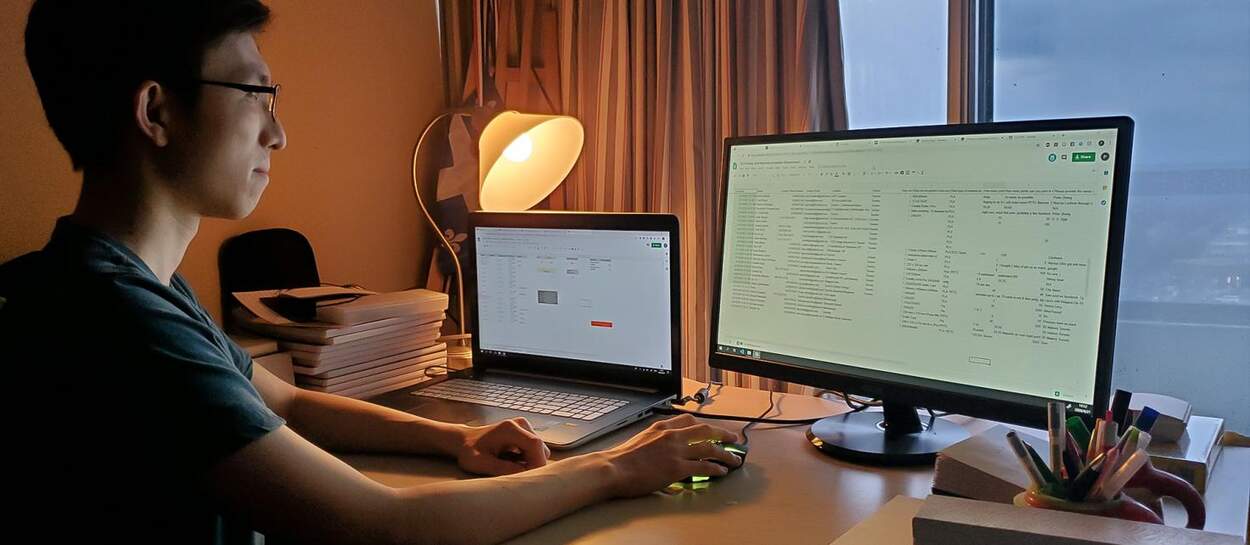

Leslie Dan Faculty of Pharmacy PharmD-MBA student Peter Zhang leads the logistical side of the 3D PPE GTHA project, coordinating more than 70 volunteer drivers who pick up and drop off equipment.

With clinical rotations paused during the COVID-19 pandemic, pharmacy students who were scheduled to be learning in a health care setting have not been able to join their supervisors on the front lines. But many have found creative ways to apply their skills and knowledge in the fight against COVID-19.

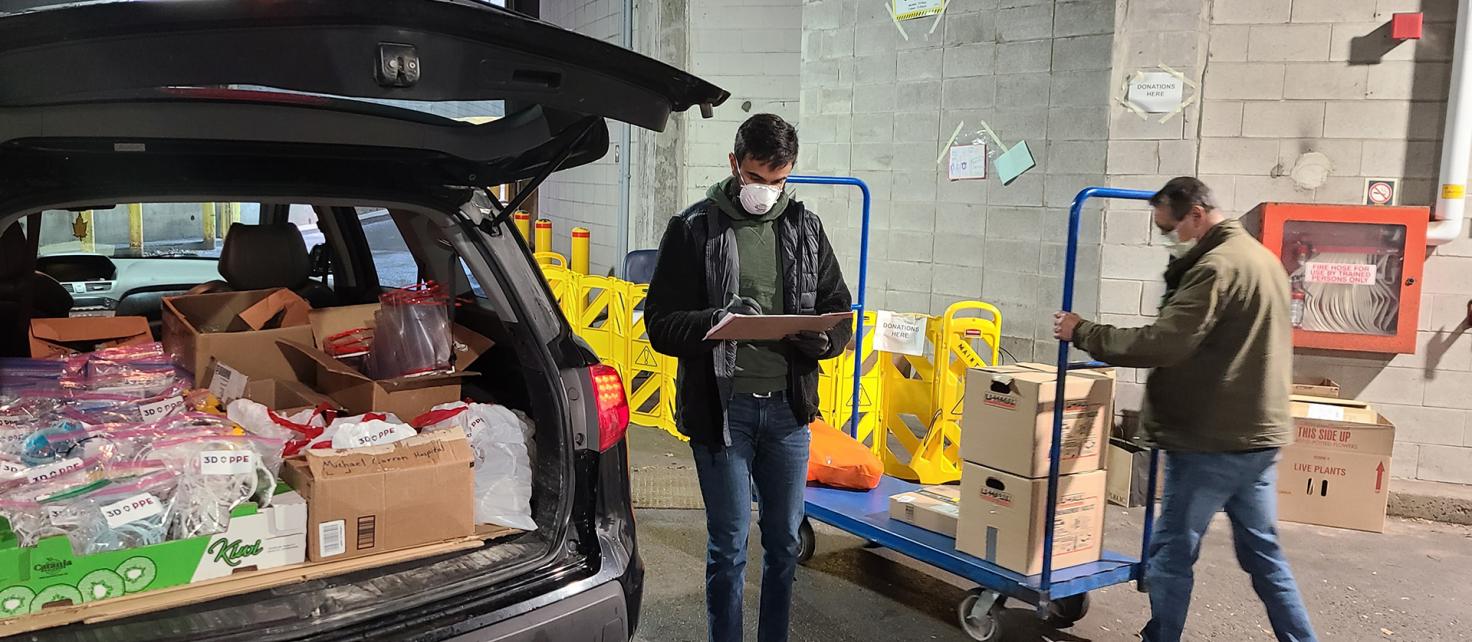

One group of U of T pharmacy and medical students are coordinating a network of 3D printers to address Ontario’s shortage of personal protective equipment (PPE) for health care workers. The resulting initiative, 3D PPE GTHA, aims to provide thousands of face shields to hospitals in Toronto and Hamilton and is even taking part in research to develop a 3D-printed N95 face mask.

“I felt a bit helpless, with preceptors on the front line but rotations paused,” says Peter Zhang, a third year PharmD/MBA student at the Leslie Dan Faculty of Pharmacy. “I started looking at different ways to contribute and considered all sorts of avenues.”

He and several other pharmacy and medical students heard about a group from Queen’s University who were providing 3D-printed PPE to health care workers. After learning best practices from the Queen’s group, they joined forces with interested McMaster University medical students and created 3D PPE GTHA.

The group has partnered with individuals, labs and businesses with 3D printers to create frames for face shields and coordinates their distribution to health care facilities. They began as just a small group of students in the last week of March and enlisted their first printer the following week. They now have a large team doing everything from research and logistics to outreach and fundraising, and coordinated the involvement of more than 90 3D printers that have already produced thousands of frames.

“We are really filling a gap that exists until industry can catch up.”

“We are really filling a gap that exists until industry can catch up,” says Zhang, who leads the logistics side of the initiative, which includes coordinating more than 70 volunteer drivers who pick up and drop off the printed PPEs. “Speed is vital.”

Research Collaboration will help develop 3D- printed face mask design

Dr. William Ng, an anesthesiologist at Toronto General Hospital and assistant professor in the U of T’s Faculty of Medicine, is 3D PPE GTHA’s physician partner. He says that the student initiative is providing vital equipment to health care workers and essential frontline personnel, while also collecting valuable information to improve the designs. “Clinically proven solutions are important, and clinical feedback from health care workers will help improve the designs,” he says. “We are very excited to give clinical input to the face shield arm of the project.”

This commitment to research and improvement isn’t limited to the face shield designs. The group is also collaborating with Dr. Ng’s team at UHN’s Advanced Perioperative Imaging Lab (APIL), as well as universities and teaching hospitals across the province, on a project to develop 3D-printed N95 face masks to help address the current mask shortage. 3D PPE GTHA will be working closely with the APIL team to develop mask prototypes and help test the face mask design.

Zhang and his fellow students have learned a lot about entrepreneurship, leadership and research through their work on this initiative and recent research collaboration. “These are unprecedented times. No one expected to encounter a pandemic while undergoing training. There’s a lot that’s out of our control, but what is in our control is what we do with this time,” says Zhang. “I may not be on rotation, but I’m still learning. I’m getting a lot out of this and contributing at the same time.”

By Eileen Hoftyzer

Related Stories

More News

Image

How Bebe Simelane’s summer research is fueling her passion for science

Through hands-on research, mentorship, and exposure to cutting-edge tools like AI, this USRP student is gaining the skills and confidence to pursue graduate studies and advance science.

Read More

Image

Faces of PharmSci: Kristy Scarfone

Co-supervised by Professor Jillian Kohler and Assistant Professor Jaris Swidrovich, MSc student Kristy Scarfone is researching how unregulated substance-related care and harm reduction vary across Ontario, with the goal of strengthening public health and showcasing pharmacists’ impact in this area.

Read More

Image

Research team aims to co-design diabetes and dementia support programs that meet community needs

Network for Health Populations funding will support collaborative project to improve health outcomes for immigrant communities in Mississauga.

Read More